Cases

Service Spotlight: Application Support – Pressure Sensitive Labels (PSL)

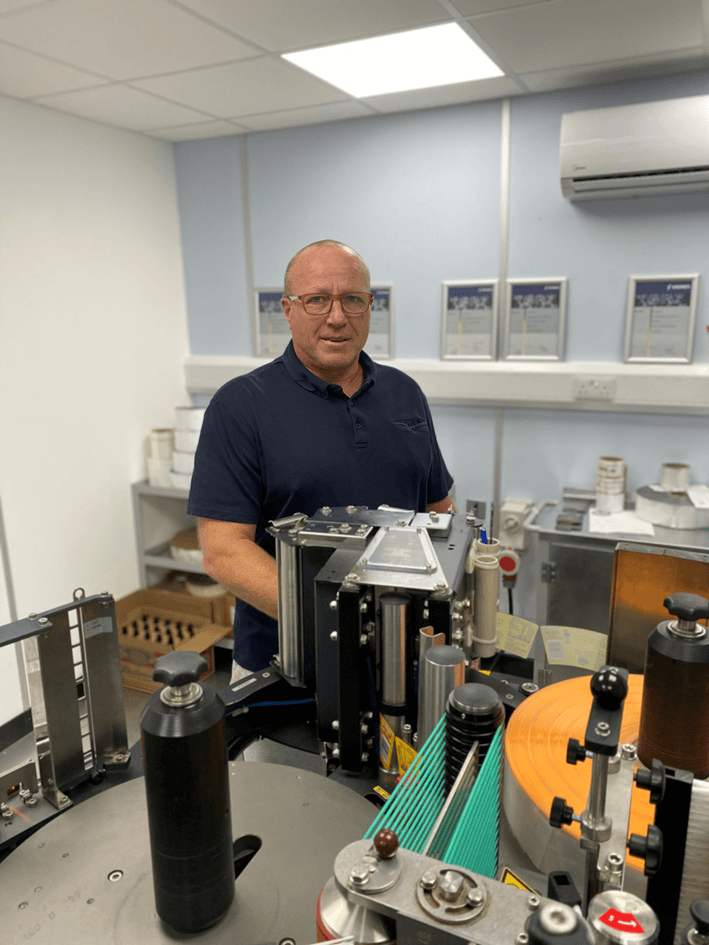

We talk to Chris Cotter – Application Engineering Manager, MCC Wales about the Intricacies of pressure sensitive label application and the importance of effective planning and training.

Share

What is your involvement in a labeling project?

Application Engineers are an integral part of the Technical Department project management team. From the initial design phase, we work with the bottle manufacturer’s drawings as well as taking into consideration the customer’s equipment and process (usually gained from a line audit/evaluation) to determine the maximum possible size of the label. This information is then taken by the Technical Project Manager to specify appropriate materials and print process.We can avoid a high percentage of potential issues at the design stage of the project but there can occasionally be unforeseen issues, which is where the second part of our role kicks in. Once the label is running on the customer’s lines, we provide on-going support for any problems that may unexpectedly arise.

Can you explain some of the common challenges you face?

With the increasing importance of sustainable products, we are seeing a trend towards thinner materials. The down gauging of the label material as well as a demand for recyclable materials can make label application a more challenging process. With the focus on sustainable packaging we have to successfully remove the label from the bottle as well as get the label onto it!

Along with this comes changes to the container, for example, the down gauging of PET preforms can have a significant effect when it comes to label application quality. A soft bottle increases the likelihood of unsightly wrinkles and bubbles forming under the label’s surface, this certainly adds to the challenge.

Climate can also be a huge factor. High temperature and humidity as well as low temperature fills can all affect the label’s performance. Label storage must be carefully considered; For example, in warmer application environments, we ship the labels in climatically controlled storage containers and when they arrive at the brewery, they go straight into controlled warehousing. There is often a case for further climatically controlled label staging areas close to the applicators.

New technologies such as linerless PSL, unique but challenging shapes, flag labels as well as further advances in recyclable and wash off materials will continue to keep us on our toes, I am sure!What is involved in a training session? With a new customer, we can offer in depth training sessions. Typically, the participants can include operators, quality, technical and procurement personnel. We are able to provide both classroom and “hands on” sessions at the applicator, to re-enforce the messages to the customer. We also provide refresher training if the customer requests. We try to cover every aspect of PS labeling including:

- Construction of the label

- Different material options

- Optimal storage and handling

- Good housekeeping

- Optimal application methods

- Fault finding and root cause analysis

How does your service really benefit a project?

We are a one-stop shop, from the very beginning we work closely with our internal and external customers to ensure the label is of optimum condition in terms of performance and application. Face to face meetings are a key part of our role. We travel extensively to visit customers and equipment manufacturers. When we are on site it is ideal, we are face to face to talk through any issues and build the confidence of the customer. Take for example, Heineken Brazil, this has recently been a huge project for MCC. Starting late 2018 I made an initial visit to initiate this project and have since been back numerous times, providing operation training sessions at each of the 4 breweries covering the 24hr shift patterns. We also developed local MCC Application Engineering Support and forged a good relationship with the applicator OEM (Krones Brazil) during these long-haul visits. When you walk away from somewhere with a built up trust and reputation, that is job satisfaction.

How are you able to continue the support during these times of travel restrictions?

Our support role is normally conducted face-toface in the field, which is not possible during these unprecedented times. In order to continue the same level of service we have developed other remote means of application support. This involves a range of methods to communicate our support such as calls, photography, video conferencing and Live Video at the applicator. We aim to maintain the same service levels to our customer for everything from drawings to application advice and troubleshooting, in these difficult times and beyond.Times are changing, our goal is to move application engineering into the next level. Watch this space!

For the HEINEKEN Group in Brazil, the experience was extremely positive, whether through constant technical visits or excellent inplace training at our factories. The partnership with MCC over the past few years has been essential in being able to deliver a quality product, which is one of our values, to our consumers. In this way, we guarantee that the HEINEKEN Group is present in every Brazilian heart and bottle!”

Thiago Guilherme, Quality Assurance Specialist, HEINEKEN Group Brazil